Automotive engine test center

An innovative synthesis of building structure and technology sets standards

Owner

BMW AG, Munich

Architect

HENN Architekten, Munich

GFA

50 000 sqm

Building Services Costs

>50 million

Scope of work

General Planning

HOAI stages

1-9

Planning time

2004 - 2008

Construction time

2006 - 2009

In 1998, KBP won an international competition to be the general planner for a new automotive engine test center at the R&D facilities of the BMW Group in Munich.

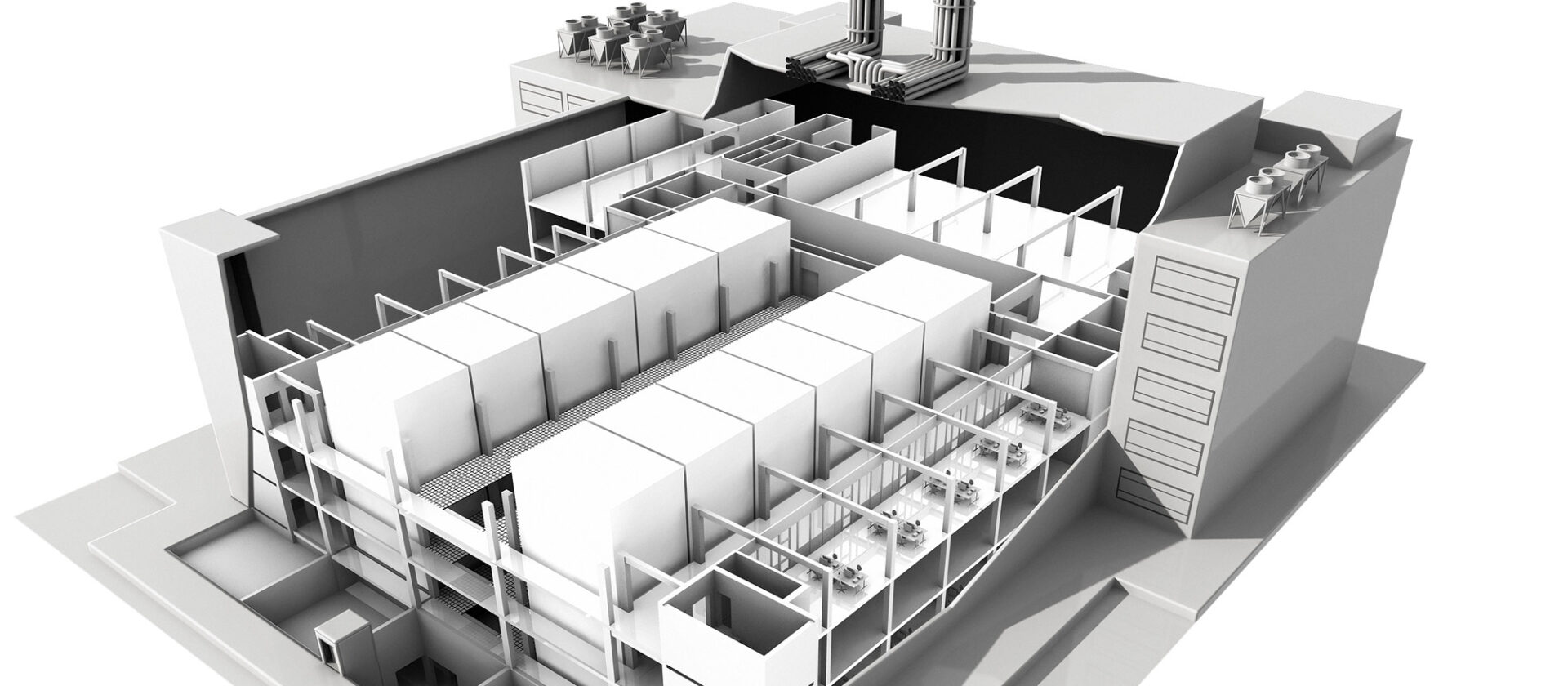

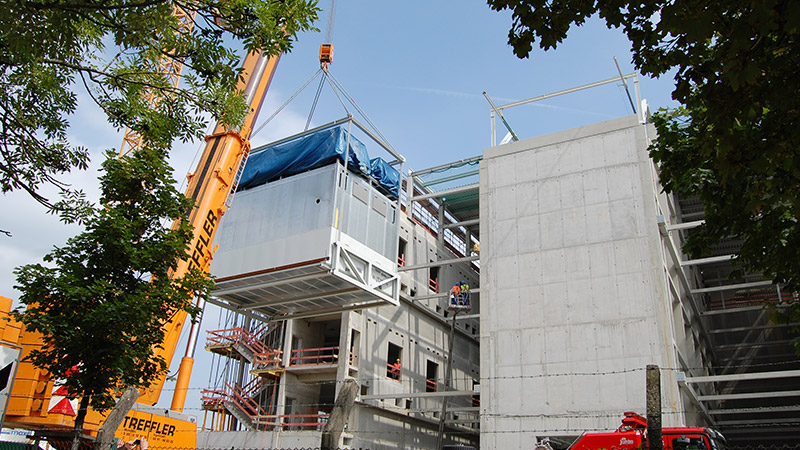

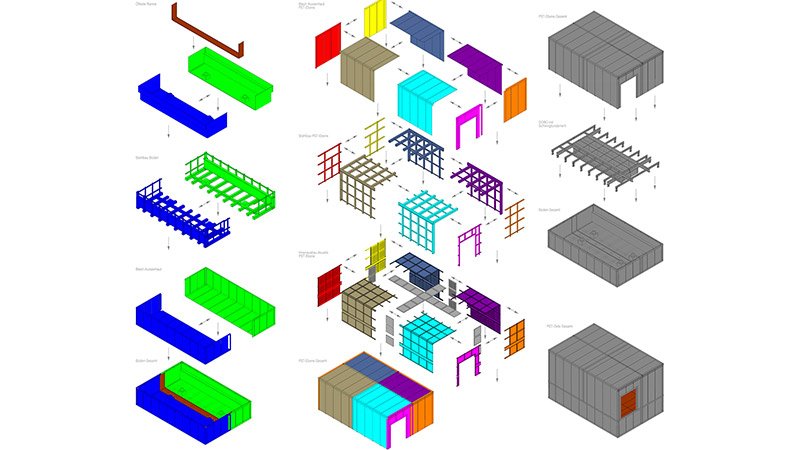

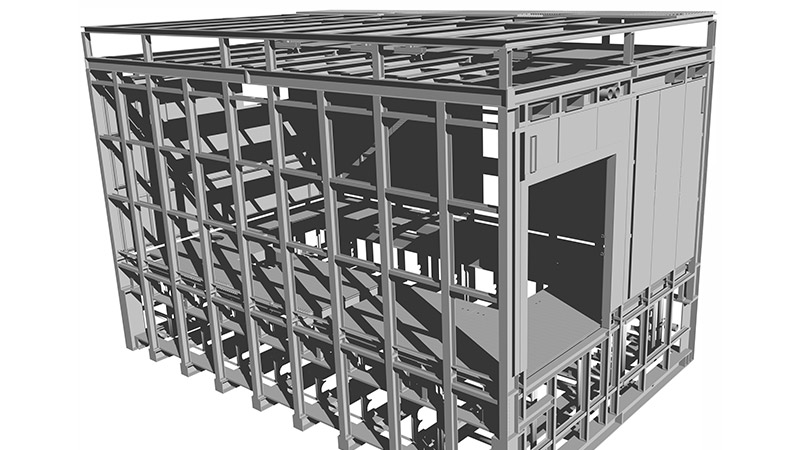

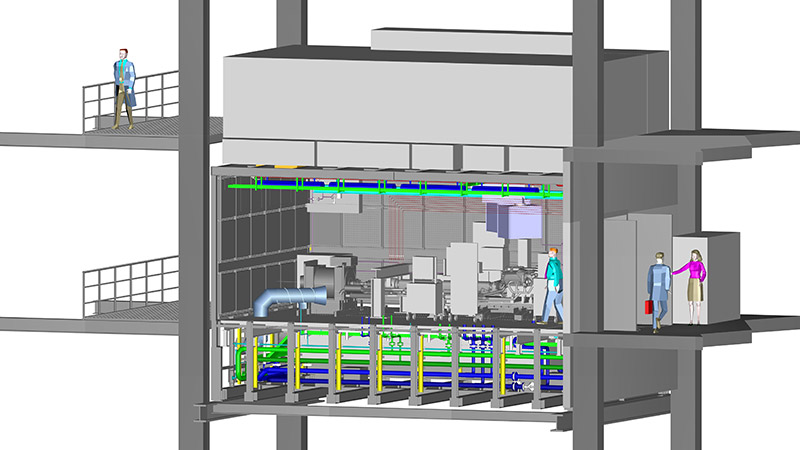

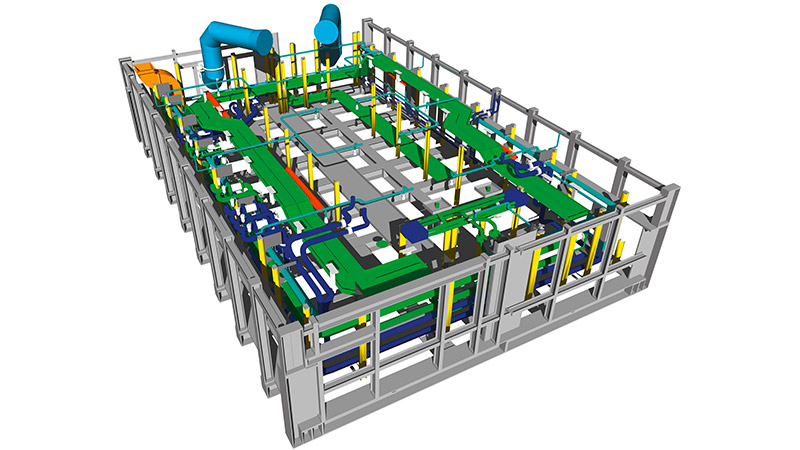

The basis for the winning design was the stacked arrangement of modular and prefabricated engine test stands. These modules are triple stacked at the two long sides of a technical center. This not only ensures an extremely compact building envelope, but also allows flexibility and a considerable reduction in construction time, while maintaining the highest quality standards.

The logical structure of the building coupled with modular design which allows varying the heights for the test stands and standard floors, creates ideal areas for offices and workshops. These are optimally integrated in the workflow of the test facility buildings.

The design, which included three interconnected buildings with different usage requirements, unites the BMW Group’s entire engine development in one location.

The first construction phase (22,000 m² gross floor area) was completed in 2002; it comprises a total of 36 engine test stands.

The second building (50,000 m² GFA ) was completed in 2009 and houses a whole range of drive and aggregate test stands:

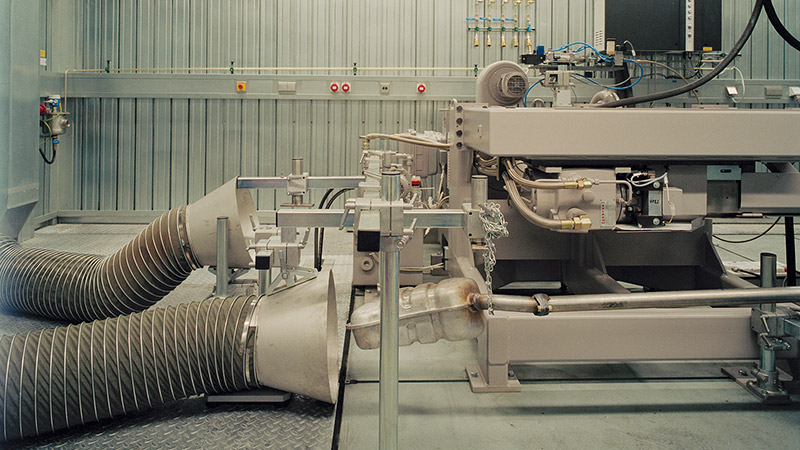

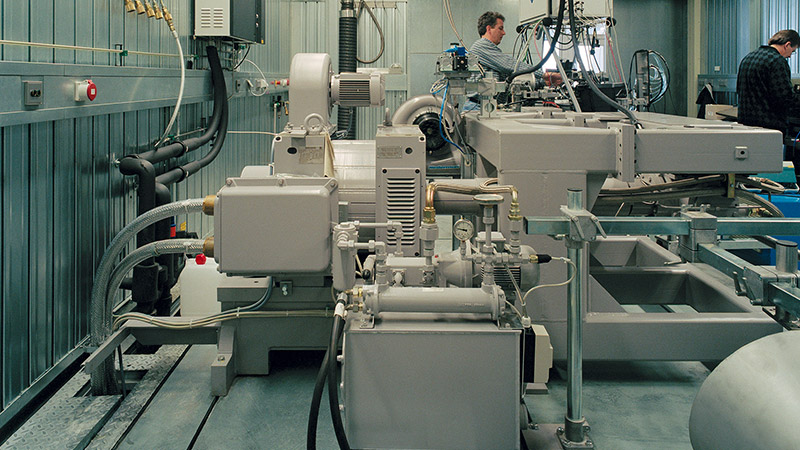

37 Motor and drive test stands with special functions for altitude climate tests, 4WD, curve travels, acoustic measurements as well as transparency test stands in laser laboratories. Gearboxes and components are tested and developped on 80 additional aggregate test stands.

The third building (30.000 m² GFA, 18 engine test stands, 12 SHED chambers and chassis dynamometer test benches) was completed in 2013.

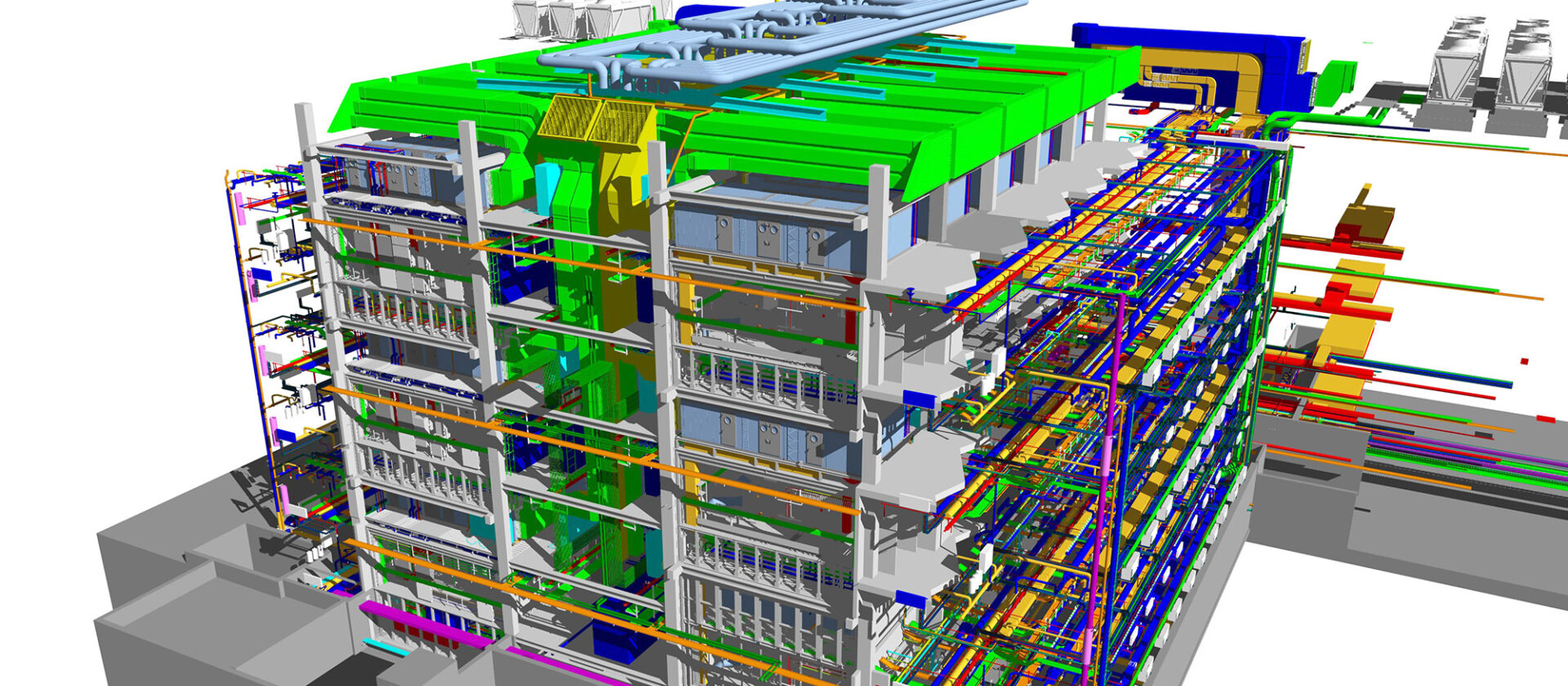

As general planning engineer, KBP was commissioned with the integrated planning of the steel construction of the test stands, in addition to planning all technical aspects of the building.

By using highly developed system architecture, KBP was able to optimally integrate the numerous essential systems and functions required for a smooth construction process.

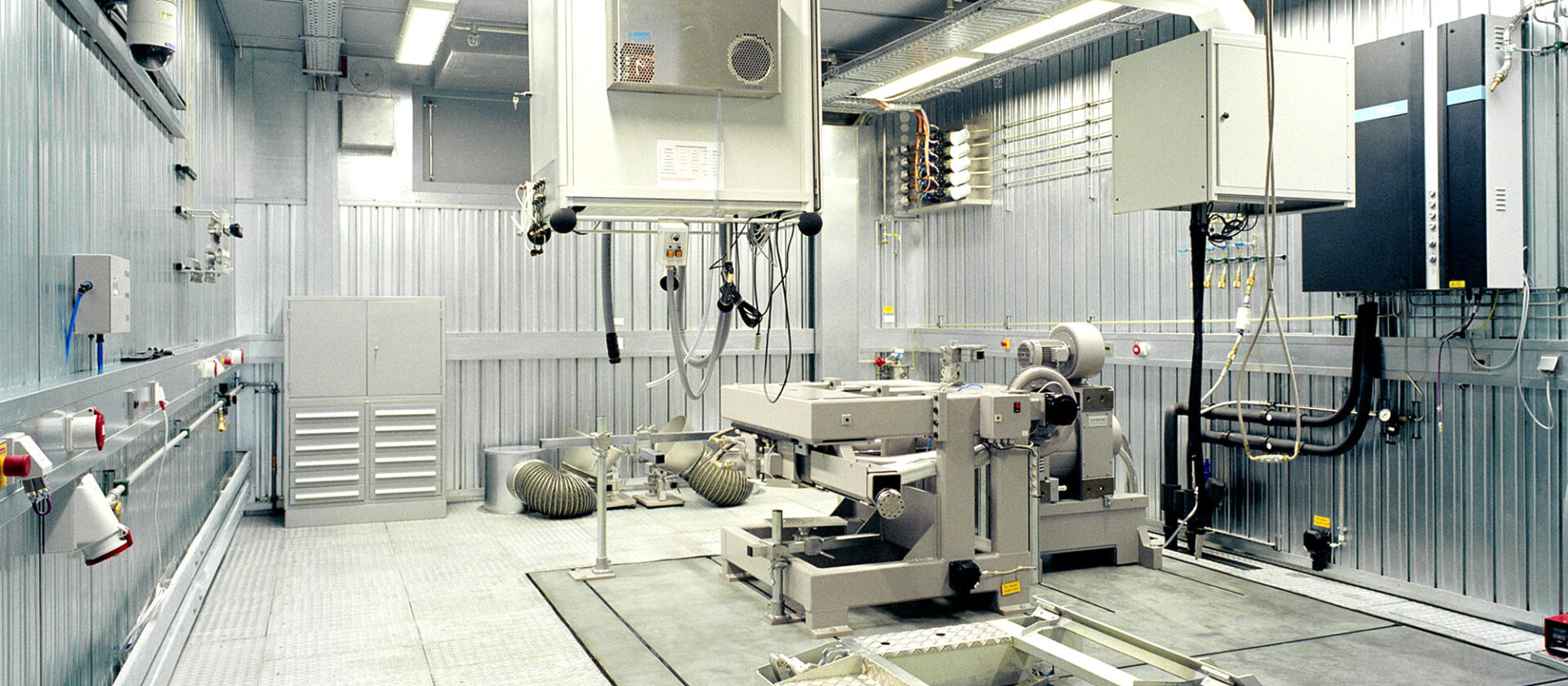

Each test stand provides its own ventilation technology. The control cabinets for the electrical and automation systems are assigned to each test stand, while the exhaust gas measuring system is positioned in the area between the test stands and measuring stations. Coolant, cold water, fuel and treatment of waste-water and waste-gases are supplied centrally. Massive construction was used for the the aggregate test stands.

In addition to the test facilities, the building includes all functions required for efficient operation, such as offices, workshops and warehouses.